Loading Dock LevelersLoading Dock Equipment

Since our inception, we’ve been dedicated on working to educate our partners on how to make their loading docks safe and productive work environments. Across the Cleveland and Akron region, we only provide superior loading dock levelers to reduce costs and equipment down-time.

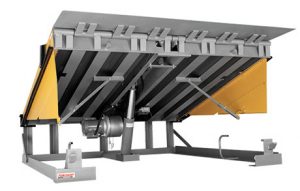

Mechanical Dock Levelers

Poweramp has engineered their line of mechanical dock levelers to focus on adding value and performance at your loading docks through easy activation and reliable, long lasting components. Mechanical dock levelers are often used on large warehouse/distribution center projects, where high capacity levelers are not required. They are also ideal for environments where power is not available or serve as an economical solution when the loading dock gets minimal usage.

Standard safety features on Poweramp’s mechanical dock levelers include pivoting cross traffic safety legs for emergency support, yieldable lip control and an integral lockout / tagout maintenance strut. We offer (3) models of PoweRamp mechanical dock levelers: the HM, CM and LMP Series. Sizes for our mechanical dock levelers include 6′, 6’6″ and 7′ standard widths and 6′, 8′ and 10′ standard lengths. Capacities offered range from 25,000 lb to 50,000 lb CIR (Comparative Industry Rating).

| Advantages | Disadvantages |

|

|

Air Powered Dock Levelers

As the middle road between mechanical and hydraulic dock levelers, Poweramp air powered dock levelers offer the ideal balance between a low cost solution and efficient, minimal maintenance operation. Air powered dock levelers are often used on applications where high capacity levelers are not required. For environmentally focused projects, Poweramp’s air powered loading dock levelers can be connected to solar panels for an easy, economical solution.

Standard safety features on Poweramp’s air bag dock levelers include pivoting cross traffic safety legs for emergency support, safety toe guards, yieldable lip control and an integral lockout / tagout maintenance strut. We offer (2) models of Poweramp air powered dock levelers: the AP and CentraAir® Series. Sizes for our air powered dock levelers include 6′, 6’6″ and 7′ standard widths and 6′, 8′ and 10′ lengths. Capacities offered range from 25,000 lb to 50,000 lb CIR (Comparative Industry Rating).

| Advantages | Disadvantages |

|

|

Hydraulic Dock Levelers

Poweramp’s hydraulic dock levelers are ideal for applications where, over the long term, key issues like safety, minimal maintenance and long life are prioritized over low initial cost, higher maintenance solutions. Hydraulic dock levelers are often used on applications where higher capacity and easy operation levelers are desired. They provide longer operating life, easy activation and minimal maintenance when compared to mechanical loading dock levelers.

Standard safety features on Poweramp’s hydraulic dock levelers include a hydraulic velocity fuse to limit free fall to 3″ (+/- 1″), safety toe guards, yieldable lip control and an integral lockout / tagout maintenance strut. We offer (4) models of Poweramp hydraulic dock levelers: the PR, VH, EH and LHP Series. Sizes for our hydraulic dock levelers include 6′, 6’6″ and 7′ standard widths and 6′, 8′, 10′ and 12′ lengths. Capacities offered range from 25,000 lb to 120,000 lb CIR (Comparative Industry Rating).

| Advantages | Disadvantages |

|

|

iDock Controller

The technologically advanced iDock Controls provide a superior and efficient interface with membrane dome button technology for ease of use and an interactive message display for valuable equipment usage data, instructions, notifications and other information. With the use of a 3-color LED light assembly, iDock Controls clearly indicate the operating conditions of your loading dock for enhanced safety. Available integration with Poweramp® dock equipment.